10 Tips for Coach Bus Maintenance Checklist

Just like a well-oiled machine, your coach bus needs regular attention to keep it running smoothly. You might think maintenance is just about fixing what's broken, but it's so much more than that. Implementing a thorough checklist not only enhances safety but also extends your vehicle's lifespan. Curious about the essential steps you should take to guarantee your bus remains in top condition? Here are ten critical tips that could transform your maintenance routine.

Inspect Fluid Levels

When inspecting fluid levels, you should begin with the engine oil, coolant, brake fluid, and transmission fluid. Start by checking the engine oil; it's essential for lubrication and prevents wear. Use the dipstick to assess the oil level and quality. If it's dark or gritty, consider a fluid analysis to determine its condition.

Next, examine the coolant in the reservoir. Proper coolant levels help regulate engine temperature and prevent overheating. Look for any signs of leaks or discoloration, which could indicate a problem.

Then, check the brake fluid. It should be clear and at the ideal level to guarantee effective braking. If it's low, inspect the brake lines for leaks. Leak detection is important, as even a small leak can compromise your safety.

Check Tire Condition

Tire condition is vital for safe and efficient coach bus operation. Regularly checking your tires helps guarantee peak performance and extends their lifespan. Start by inspecting the tire pressure; it should align with the manufacturer's specifications, typically found on a sticker inside the driver's door or in the owner's manual. Under-inflated tires can lead to increased fuel consumption and reduced handling, while over-inflated tires can cause uneven wear and a harsh ride.

Next, assess the tread depth. Use a tread depth gauge or the penny test—insert a penny into the tread with Lincoln's head down. If you can see all of Lincoln's head, it's time to replace the tire. Maintaining adequate tread depth is vital for traction, especially in wet conditions.

Don't forget to check for any visible damage, such as cuts, cracks, or bulges, which can compromise tire integrity. Finally, verify your tires are rotated regularly to promote even wear. By paying attention to tire pressure and tread depth, you'll enhance safety, improve fuel efficiency, and enjoy the freedom of the open road without worry.

Test Braking System

Regularly testing the braking system is essential for guaranteeing the safety and reliability of your coach bus. Start by inspecting the brake pads for wear. Worn brake pads can considerably reduce stopping power, posing a serious risk during travel. If you find the pads are thin or uneven, replace them immediately to maintain the best braking performance.

Next, check the hydraulic fluid levels. Low hydraulic fluid can lead to brake failure, so verify that the reservoir is filled to the proper level. If you notice any leaks around the brake lines or connections, address them right away; even small leaks can result in a loss of pressure and compromise your bus's braking ability.

Perform a functional test of the brake system by engaging the brakes at various speeds. Listen for any unusual noises, like grinding or squeaking, which may indicate further issues. Finally, consider using a professional brake diagnostic tool to assess the system thoroughly. This proactive approach will help you identify potential problems early, guaranteeing your coach bus remains safe and reliable on the road. Regular maintenance is key to enjoying the freedom of travel without worry.

Review Electrical Components

One essential aspect of coach bus maintenance is reviewing the electrical components to guarantee peak performance and safety. Start with battery maintenance; verify the battery terminals are clean and free of corrosion. Check the charge levels and connections, as a weak battery can lead to unexpected breakdowns.

Next, perform a thorough wiring inspection. Look for any signs of wear, fraying, or damage on the wiring harnesses. Pay close attention to connections, as loose or corroded wires can create electrical shorts or system failures.

Verify the functionality of all electrical systems, including lights, signals, and dashboard indicators. Test the fuses and relays to confirm they're operational; replacing any faulty components promptly can prevent more significant issues down the road.

Don't forget to check the alternator's performance, as it's essential for maintaining battery charge while the bus is running. Regularly reviewing these electrical components keeps your coach bus running smoothly and enhances safety for both you and your passengers. By staying proactive, you can enjoy the freedom of the open road without worrying about electrical failures.

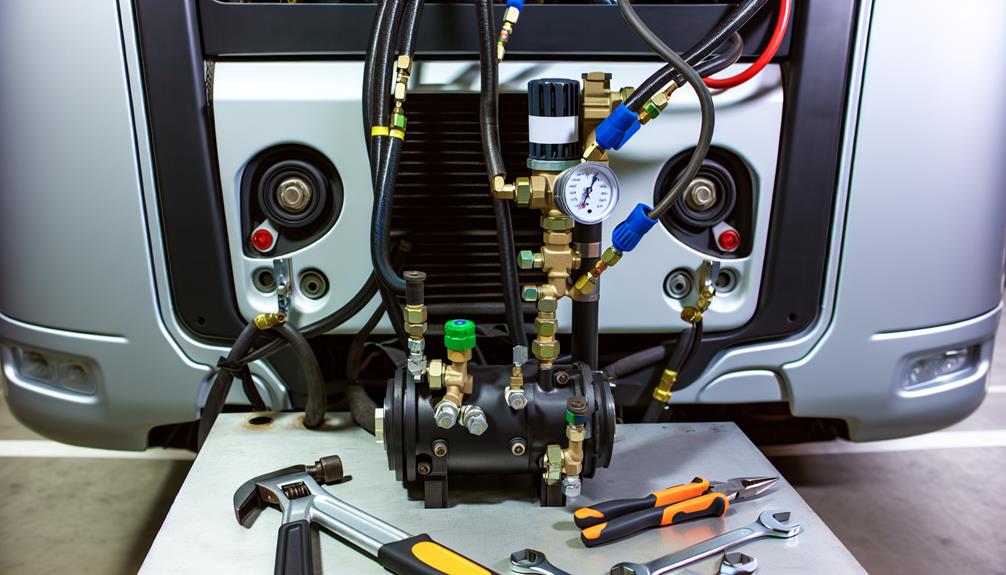

Examine Air Conditioning

After verifying the electrical components are in top shape, turn your attention to the air conditioning system. A well-functioning AC unit is essential for maintaining passenger comfort and safety, especially during long journeys. Here's a checklist to help you assess the system's performance:

- Check Refrigerant Levels: Inspect the refrigerant levels to confirm they're within the manufacturer's specifications. Low levels can severely impact cooling efficiency.

- Inspect Condenser and Evaporator Coils: Clean any dirt or debris from the coils, as they can hinder heat exchange and reduce overall cooling performance.

- Examine Hoses and Connections: Look for signs of wear, leaks, or cracks in the hoses. Damaged hoses can lead to refrigerant loss, compromising the AC's effectiveness.

- Test the Thermostat: Verify the thermostat is functioning correctly and accurately reflects the temperature. A malfunctioning thermostat can cause inconsistent cooling.

Monitor Engine Performance

Monitoring engine performance is essential for ensuring the overall reliability and efficiency of your coach bus. Regularly checking engine diagnostics allows you to identify potential issues before they escalate into costly repairs or downtime. Start by reviewing performance metrics such as fuel efficiency, temperature readings, and RPM levels. These indicators provide valuable insights into how well your engine operates under various conditions.

Utilize onboard diagnostics systems to gather real-time data on engine performance. This technology helps you pinpoint anomalies and assess the effectiveness of components like fuel injectors and spark plugs. Pay attention to warning lights and error codes, as they can signal underlying problems that require immediate attention.

Establish a routine schedule for engine performance checks, ideally at every fueling or maintenance stop. Document your findings to track trends over time; this can help you predict when maintenance is needed, ensuring that your bus stays in top shape. By keeping a close eye on engine performance, you not only enhance safety but also maximize the freedom of your journeys, allowing you to focus on providing exceptional experiences for your passengers.

Clean and Lubricate Parts

Regular engine performance checks lead to a more effective maintenance routine that includes cleaning and lubricating parts. Properly maintaining your coach bus not only enhances its longevity but also guarantees a smooth ride for your passengers. Here are essential steps to follow:

- Identify Parts Needing Attention: Check belts, hoses, and filters for dirt and wear.

- Use Appropriate Cleaning Techniques: Employ degreasers and non-abrasive cleaners to remove grime. For metal components, consider ultrasonic cleaning for a deep clean.

- Apply Lubrication Methods: Choose the right lubricant for each part. Grease is ideal for bearings, while oil is better for engine components. Confirm you're using products that meet manufacturer specifications.

- Regularly Inspect After Cleaning: Once clean, inspect parts for damage or wear. Address any issues immediately to prevent further complications.

Assess Safety Equipment

Securing the safety of passengers and drivers hinges on a thorough assessment of safety equipment. Regularly evaluating your safety gear not only meets safety standards but also guarantees that emergency procedures can be executed seamlessly when needed.

Here's a simple checklist to guide your assessment:

| Safety Equipment | Action Required |

|---|---|

| Fire Extinguishers | Check expiration dates; verify accessibility. |

| First Aid Kits | Verify contents; restock as necessary. |

| Emergency Exits | Inspect for functionality; verify clear signage. |

Make it a habit to check these items routinely. Fire extinguishers should be easily reachable, and first aid kits must be well-stocked to handle any incidents. Additionally, always verify that emergency exits are operational and that passengers are familiar with their locations. This proactive approach not only enhances safety but also fosters a sense of freedom for passengers, knowing that their well-being is prioritized. Remember, proper maintenance of safety equipment is essential in creating a secure environment. Implement these assessments regularly to uphold your commitment to safety.

Schedule Regular Inspections

Scheduling routine inspections is essential for maintaining the operational integrity of your coach bus. By adhering to a structured maintenance frequency, you can proactively identify issues before they escalate, guaranteeing both safety and reliability for your passengers.

Here's a concise inspection checklist to follow:

- Fluid Levels: Check engine oil, coolant, brake fluid, and transmission fluid to assure peak performance.

- Tires: Inspect tire pressure, tread depth, and overall condition to enhance safety and fuel efficiency.

- Braking System: Evaluate brake pads, rotors, and hydraulic systems for wear and functionality.

- Lights and Indicators: Verify all exterior and interior lights are operational, including turn signals, brake lights, and hazard lights.

Incorporating these inspections into your routine will help you maintain your coach bus effectively. By using an inspection checklist, you can ensure no detail is overlooked. Regular inspections don't just prevent costly repairs; they also contribute to a smoother, more enjoyable travel experience for everyone on board. So, make it a priority to schedule these inspections and keep your coach bus in top shape.

Maintain Interior Cleanliness

After completing routine inspections, maintaining interior cleanliness plays an essential role in the overall upkeep of your coach bus. A clean interior not only enhances passenger comfort but also prolongs the life of your interior upholstery. Start by establishing a regular cleaning schedule. Daily, remove trash and debris, ensuring that the aisles and seat areas are clear. Weekly, vacuum the floors and seats to eliminate dirt and allergens that can accumulate.

For the upholstery, use appropriate cleaning solutions designed for the fabric type. Spot clean stains immediately to prevent them from setting, as neglected spills can lead to permanent damage. Additionally, consider using fabric protectants to shield your upholstery from future stains.

Don't forget about the windows and mirrors; clean them regularly for peak visibility and aesthetic appeal. Finally, inspect your bus for any unpleasant odors and address them promptly with air fresheners or deep cleaning as needed. By prioritizing interior cleanliness, you not only create a welcoming environment for passengers but also maintain the value and integrity of your coach bus.

https://myprevost.net/wp-content/uploads/2024/09/728x90.jpg