10 Tips for Fixing Prevost Coach Bus Electrical Problems

Imagine you're on a long trip in your Prevost Coach, and suddenly, the lights flicker and the engine stalls. This scenario underscores the importance of properly addressing electrical issues in your bus. By taking a systematic approach, you can tackle these problems effectively. From checking battery connections to consulting professional technicians, there are essential steps you shouldn't overlook. What common pitfalls should you be aware of, and how can you avoid them? Let's explore these tips to guarantee your travels remain uninterrupted.

Check the Battery Connections

One of the first steps in diagnosing electrical issues in your Prevost coach bus is to check the battery connections. You'll want to verify that both positive and negative terminals are clean and securely fastened. Corrosion can lead to poor connection integrity, so inspect for any signs of buildup. If you see corrosion, remove it carefully using a wire brush or a mixture of baking soda and water.

Next, confirm that the cables are in good condition—no fraying or exposed wires. Verify that the connections are tight but not overly tightened, as this can damage the terminals. Regular battery maintenance isn't just a good practice; it's vital for reliable performance on the road.

While you're at it, check the battery voltage with a multimeter. A reading below 12.4 volts suggests your battery might be undercharged or failing. If everything checks out but issues persist, it might be time to look deeper into your system. Maintaining connection integrity is essential for guaranteeing your bus runs smoothly and you can continue to enjoy the freedom of the open road.

Inspect Fuses and Relays

When troubleshooting electrical problems in your Prevost coach bus, inspecting fuses and relays is an important step. These components play an essential role in your bus's electrical system, and understanding their functions can save you time and hassle.

- Check for blown fuses

- Identify the correct fuse types

- Understand relay functions

Start by locating the fuse box, which is usually found near the driver's seat or under the dashboard. Examine each fuse visually, looking for any that appear burnt or broken. If you find a blown fuse, replace it with one of the same amperage to avoid further issues. Different fuse types, such as blade, glass, or cartridge, can be present, so make sure you're using the correct replacement.

Next, inspect the relays. These components help control high-current circuits and can malfunction, disrupting vital functions like headlights or engine systems. Test each relay by swapping it with a similar one known to be functioning. If the problem resolves, you've pinpointed the faulty relay. Regularly inspecting fuses and relays not only helps maintain your bus's performance but also grants you the freedom to travel without electrical worries.

Test Circuit Breakers

Regularly testing circuit breakers is essential for maintaining the electrical integrity of your Prevost coach bus. Circuit breakers protect your system from overloads and shorts, so you need to guarantee they're functioning correctly. Start by identifying the main circuit panel and locating each breaker. Use a multimeter set to the continuity setting for circuit testing.

Begin your troubleshooting techniques by turning off all connected electrical devices. Next, remove the cover of the circuit breaker and check for visible signs of damage, like burn marks or cracked casing. With the multimeter probes, touch the terminals of the breaker. If the multimeter shows continuity, the breaker is functional. If it doesn't, you'll need to replace it.

After testing, reset each breaker by flipping it to the off position and then back to on. This action can sometimes clear minor issues. Always remember to wear appropriate safety gear while performing these tests. Regular checks can prevent unexpected electrical failures and guarantee you enjoy the freedom of the open road without interruptions. Keep your electrical system in top shape, so you can focus on your adventures.

Examine Wiring Harness

Frequently examining the wiring harness on your Prevost coach bus is essential for identifying potential electrical issues. A thorough inspection guarantees wiring integrity and proper harness routing, keeping your journey smooth and worry-free. Here's what you should focus on:

- Look for wear and tear: Check for frayed wires or damaged insulation that could lead to shorts.

- Inspect connections: Verify all connectors are secure and free of corrosion, which can disrupt electrical flow.

- Review routing: Confirm the harness isn't pinched or rubbing against sharp edges, which can cause chafing over time.

When you examine your wiring harness, don't overlook the importance of its overall condition. A well-maintained harness contributes considerably to the electrical reliability of your coach. Regular checks can help catch issues before they escalate into major problems, offering you the freedom to travel without unexpected interruptions. Keep your wiring harness in ideal shape, and you'll enjoy a more reliable and enjoyable driving experience. Remember, taking proactive steps now can save you time and money later, guaranteeing your adventures remain uninterrupted.

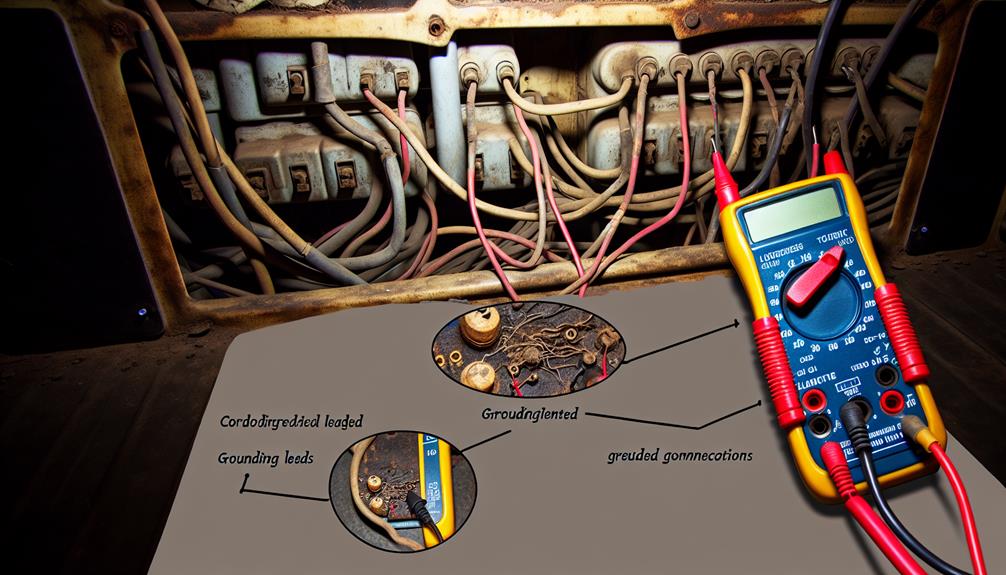

Identify Grounding Issues

To tackle grounding issues in your Prevost coach bus, start by checking all grounding points and connections. Grounding techniques are critical for maintaining electrical safety and guaranteeing your bus operates smoothly. Focus on the main grounding strap, often located near the battery. Confirm it's tight and free of corrosion.

Next, inspect grounding connections throughout the electrical system, including lights and appliances. Loose or corroded connections can lead to erratic behavior or complete failure. Clean any corrosion using a wire brush or an appropriate cleaner, and secure connections firmly.

Don't overlook the chassis ground. It's essential for the overall electrical integrity of your bus. Make sure it's securely fastened to the frame, and check for any paint or rust that might interfere with the connection.

Use a Multimeter

Using a multimeter is essential for diagnosing electrical problems in your Prevost coach bus. This versatile tool allows you to measure voltage, current, and resistance, providing insight into your bus's electrical system. Mastering multimeter usage will enhance your troubleshooting techniques, enabling you to pinpoint issues more effectively.

- Check for voltage drops that could indicate faulty connections.

- Measure resistance to identify short circuits or open circuits.

- Test continuity to verify all components are functioning properly.

To get started, set your multimeter to the appropriate mode based on what you're testing. For voltage checks, confirm the probes are connected correctly, and read the display for accurate measurements. When measuring resistance, disconnect power to avoid damage to the multimeter.

If you encounter unusual readings, cross-reference with the bus's wiring diagrams to identify potential faults. By following these steps, you empower yourself to tackle electrical issues with confidence. A well-maintained electrical system means more freedom on the road, so take the time to understand your tools and processes. With a multimeter in hand, you can keep your Prevost coach bus running smoothly.

Verify Power Sources

Before diving into repairs, it's crucial to verify your power sources to confirm they're functioning correctly. Start by checking your battery connections. Loose or corroded terminals can disrupt power distribution, causing various electrical issues. Ascertain that all connections are tight and clean.

Next, inspect the main power supply. Look for any signs of wear or damage that could impede performance. If you've made recent electrical upgrades, double-check that these modifications comply with your bus's specifications. Sometimes, new components can inadvertently overload existing circuits, leading to failures.

Utilize a multimeter to measure voltage at the battery and various points throughout the electrical system. You should see consistent voltage readings; significant drops may indicate a problem in the wiring or connections.

Don't forget to confirm that your fuses are intact and rated correctly for your system. A blown fuse can disrupt power flow, causing critical systems to fail.

Lastly, keep an eye on your alternator's output. If it isn't generating sufficient voltage, it won't recharge your batteries effectively. Identifying these issues early guarantees your Prevost Coach stays reliable on the road.

Look for Corrosion

When inspecting your Prevost Coach's electrical system, pay close attention to corrosion, as it can greatly impair performance. Corrosion can cause poor connections, leading to electrical failures that impact your driving experience. Regular checks can help you catch these issues early.

Here are a few key areas to inspect:

- Battery terminals and connections

- Ground connections and wiring harnesses

- Circuit breakers and fuse panels

To guarantee effective corrosion prevention, use dielectric grease on connections and terminals. This simple addition acts as a barrier against moisture and contaminants, extending the lifespan of your electrical components. It's crucial to incorporate corrosion prevention into your routine electrical maintenance.

If you spot any corrosion, clean it immediately using a wire brush or a specialized corrosion remover. After cleaning, apply a protective coating to prevent future buildup. Remember, consistent inspections and maintenance can keep your electrical system functioning smoothly, allowing you to enjoy the freedom of the open road without worry. Don't underestimate the impact of corrosion; a proactive approach will save you time and hassle in the long run.

Review Electrical Schematics

After addressing corrosion issues, the next step is to review the electrical schematics of your Prevost Coach. Understanding diagrams is essential for diagnosing electrical problems effectively. Start by locating the specific schematics for your bus model; these will guide you through the various circuits and components.

Pay close attention to the power flow in the diagrams. Trace the connections from the battery to the electrical components, noting any discrepancies or potential breakpoints. Use troubleshooting techniques like voltage testing at key junctions to confirm that power is reaching the necessary areas.

If you spot a broken connection or a short circuit, you can often resolve these issues with simple repairs, such as replacing damaged wires or connectors. Keep in mind that a good schematic will also indicate ground points; ensuring these are intact is critical for proper function.

Consult Professional Technicians

If you're unable to pinpoint the source of the electrical issue, consulting professional technicians can save you time and guarantee a proper diagnosis. These experts are equipped with advanced diagnostic tools and possess the experience needed to tackle complex electrical problems in your Prevost Coach Bus.

Consider the following benefits of seeking professional help:

- Accurate Diagnosis: Technicians use specialized diagnostic tools to identify the root cause of your electrical issues quickly and accurately.

- Effective Troubleshooting Techniques: They apply proven troubleshooting techniques that can resolve problems efficiently, minimizing downtime.

- Peace of Mind: Knowing that qualified professionals are handling your bus's electrical system allows you to focus on your travels without worry.

Attempting to solve intricate electrical problems without the right expertise can lead to further complications. Professionals understand the nuances of your bus's system, ensuring that repairs are done correctly. By consulting technicians, you're not just fixing an issue; you're investing in the longevity and reliability of your Prevost Coach. Trust their knowledge and experience to keep you on the road, enjoying the freedom you desire.

https://myprevost.net/wp-content/uploads/2024/09/728x90.jpg