What Are Common Electrical Issues in Coach Buses?

You might be surprised to learn that electrical issues are among the most common problems faced by coach buses. When you're on the road, a malfunctioning electrical system can lead to serious complications, impacting everything from passenger safety to overall performance. Have you ever considered how issues like battery drain or faulty alternators could disrupt a trip? Understanding these common electrical challenges is essential for maintaining a reliable fleet, and there's much more to explore regarding how they can be identified and resolved effectively.

Battery Drain Problems

Battery drain problems are a common headache for coach bus operators, often stemming from various electrical issues. To tackle this challenge effectively, you'll want to implement solid battery maintenance tips and power management strategies. Start by regularly inspecting the battery terminals for corrosion, which can impede performance. Clean them with a mixture of baking soda and water to guarantee a seamless connection.

Next, consider the age of your batteries. Most batteries have a lifespan of around four to six years. If you notice a decline in performance, it might be time to replace them. Keep an eye on your bus's electrical loads too. Excessive use of onboard electronics without proper power management can lead to significant battery drain.

Utilizing smart charging techniques is another key strategy. Opt for a smart charger that can monitor battery health and prevent overcharging. Implementing deep cycle discharge practices can also extend battery life, allowing for longer periods between charges. By following these battery maintenance tips and adopting effective power management strategies, you'll enhance the reliability of your coach buses and guarantee peak performance, giving you the freedom to focus on what matters most—your passengers.

Faulty Alternator Issues

Diagnosing faulty alternator issues is vital for maintaining the electrical integrity of your coach bus. The alternator plays an essential role in charging the battery and powering the electrical systems. If you're experiencing electrical problems, it might be time for some alternator testing.

Here are common signs of alternator issues:

- Dimming or flickering lights

- Warning light on the dashboard

- Dead battery after short periods of use

- Unusual noises like grinding or whining

- Electrical accessories not functioning properly

When you notice these symptoms, start with voltage regulation checks. A failing alternator often leads to inconsistent voltage output, which can cause various electrical malfunctions. Use a multimeter to measure the voltage at the battery with the engine running; it should read between 13.5 and 14.5 volts. If it's lower, your alternator might be struggling to charge the battery effectively.

Addressing faulty alternator issues promptly can help avoid further complications and guarantee that your coach bus continues to run smoothly. Remember, maintaining your electrical systems allows you to enjoy the freedom of the open road without unexpected disruptions.

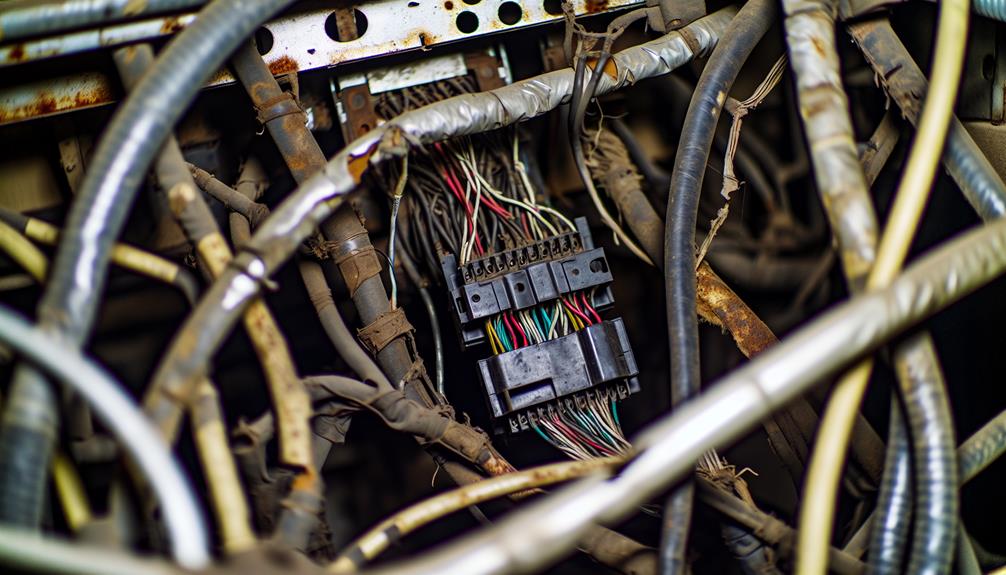

Wiring Harness Failures

When you're troubleshooting electrical issues in a coach bus, wiring harness failures can often be a hidden culprit. The wiring harness connects various electrical components, and any damage can lead to malfunctions. Pay close attention to wire insulation, as it protects against environmental factors. Over time, exposure to heat or moisture can cause insulation degradation, leading to shorts or open circuits.

Another common issue is connector corrosion. This can occur due to moisture ingress, which can lead to poor connections and intermittent failures. Regular inspections can help catch these problems early.

Here's a breakdown of common wiring harness failure types:

| Failure Type | Symptoms | Possible Causes |

|---|---|---|

| Insulation Damage | Shorts, flickering lights | Heat, wear and tear |

| Connector Corrosion | Intermittent issues | Moisture, contamination |

| Loose Connections | Unstable performance | Vibration, poor assembly |

Blown Fuses and Relays

Wiring harness failures can often lead to symptoms that mask underlying issues, such as blown fuses and relays. When these components fail, you'll notice disruptions in your electrical system, which can impact safety and functionality. Understanding how to address these issues is vital for maintaining the freedom of your travels.

Here are some common signs of blown fuses and relays:

- Inoperative accessories (lights, HVAC, etc.)

- Flickering or dimming lights

- Unresponsive dashboard indicators

- Burning smells near electrical components

- Frequent electrical system resets

To tackle blown fuses, you'll want to employ proper fuse replacement techniques. Always replace a blown fuse with one that matches the amperage rating to avoid further issues. For relay problems, utilize effective relay testing methods to ascertain each relay functions correctly. This involves checking the relay's resistance and verifying voltage at the terminals.

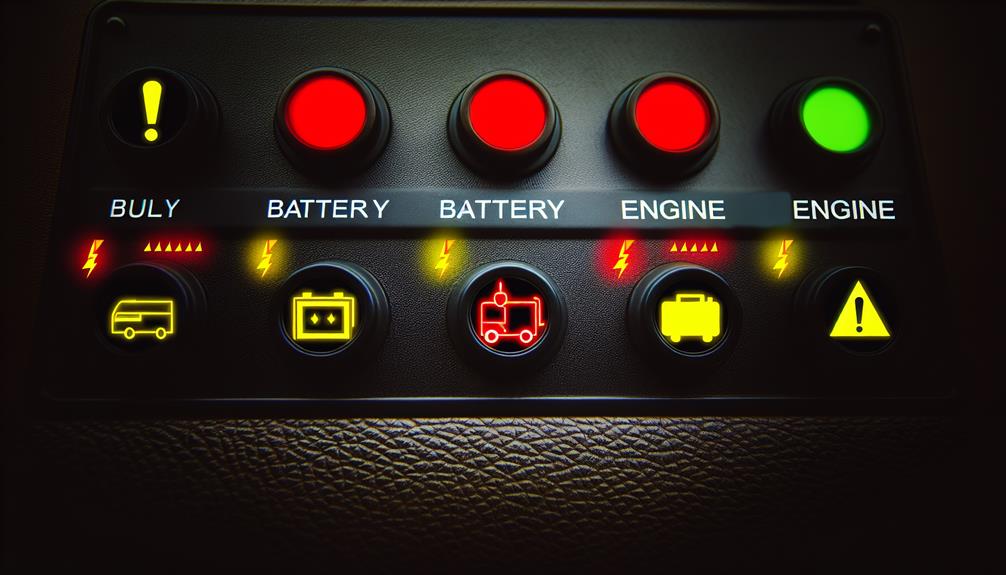

Dashboard Warning Lights

Dashboard warning lights serve as a significant communication tool between your coach bus and you, indicating potential issues within the vehicle's systems. These warning light indications are essential for effective dashboard diagnostics, allowing you to identify problems before they escalate into major failures.

When a warning light illuminates, it often correlates to specific systems, such as the engine, brakes, or electrical components. For instance, a check engine light may signal an issue with engine performance or emissions controls, while a battery warning light could indicate charging system malfunctions. Understanding these indicators empowers you to make informed decisions about maintenance and repairs.

In addition, it's important to regularly monitor the dashboard for any new warnings. Ignoring these lights can lead to further complications, such as reduced performance or safety hazards. Always refer to your coach bus manual for detailed explanations of each warning light and their implications.

Inoperative Lighting Systems

Inoperative lighting systems can pose significant safety risks for coach bus operations, especially when you're depending on clear visibility during travel. It's essential to address any lighting issues promptly through effective lighting circuit troubleshooting. Not only will this enhance safety, but it can also save you time and money in the long run.

When you encounter lighting problems, consider these common causes:

- Faulty bulbs: Check if the LED bulb upgrades you installed are functioning correctly.

- Wiring issues: Inspect the wiring for damage or corrosion, which can interrupt the circuit.

- Blown fuses: A blown fuse can disrupt your lighting system, so make sure you replace any faulty fuses.

- Switch malfunctions: Test the switches controlling the lights to confirm they're operational.

- Grounding problems: Poor grounding can lead to flickering lights or complete failure.

Air Conditioning Electrical Faults

Air conditioning systems are vital for maintaining passenger comfort on long journeys, but electrical faults can render them ineffective. If you're experiencing issues, it's important to diagnose the problem efficiently. Common electrical faults often stem from malfunctioning air conditioning sensors or problems within the HVAC control system.

Here's a quick reference table to help you identify these faults:

| Issue | Symptoms |

|---|---|

| Faulty Air Conditioning Sensors | Inconsistent temperature readings |

| HVAC Control Malfunction | Unresponsive climate controls |

| Wiring Problems | Blown fuses or burnt wires |

| Refrigerant Leak | Weak airflow or warm air output |

When air conditioning sensors fail, they can send incorrect signals to the HVAC control system, leading to ineffective cooling. You might notice temperature fluctuations or a complete lack of response from the system. Verify the HVAC control unit is functioning correctly; otherwise, your passengers may experience uncomfortable conditions. Regular maintenance and prompt fault diagnosis can prevent these issues, allowing you to travel freely and comfortably. Keep your systems in check, and you'll guarantee a pleasant journey for everyone on board.

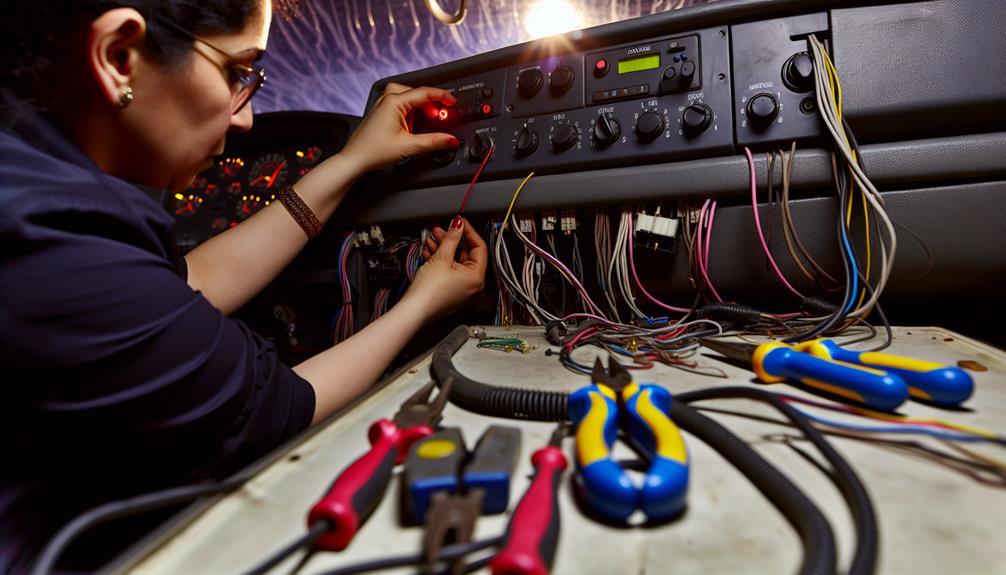

Instrument Cluster Malfunctions

When air conditioning issues are resolved, another electrical challenge that often arises in coach buses is instrument cluster malfunctions. These problems can disrupt your driving experience, making it important to address them promptly. Common symptoms of instrument cluster malfunctions include:

- Faulty speedometer readings

- Inaccurate fuel gauge levels

- Warning lights that won't turn off

- Cluster display errors

- Non-functional odometer

One primary cause of these issues is improper instrument cluster calibration. When the calibration is off, you may find that the information displayed is inaccurate or inconsistent. It's critical to regularly check and recalibrate your instrument cluster to guarantee that all gauges and indicators function correctly.

If you encounter cluster display errors, these could indicate deeper electrical issues, such as faulty connections or damaged circuit boards. Addressing these problems quickly can save you from more significant repairs down the line. In this fast-paced world, staying informed and proactive about instrument cluster maintenance can grant you the freedom to drive confidently, knowing your bus's key statistics are accurate and reliable.

Power Accessory Failures

Many coach bus operators face power accessory failures that can greatly impact the comfort and functionality of their vehicles. These issues often arise from inconsistent power supply, which can lead to malfunctioning accessories like heating systems, lights, and entertainment units. If your accessories aren't receiving the correct voltage, they won't function as intended, causing inconvenience for both operators and passengers.

It's essential to guarantee accessory compatibility with your bus's electrical system. Mismatched components can exacerbate power accessory failures, creating additional strain on the power supply and potentially leading to more significant electrical issues. For instance, if an accessory is designed for a different voltage or current rating, it may draw more power than your system can handle, resulting in blown fuses or damaged wiring.

Regular maintenance checks can help identify these problems before they escalate. Inspect connectors, wiring, and the overall power supply to guarantee everything is functioning properly. Keeping a close eye on accessory compatibility will not only extend the lifespan of your components but also maintain the comfort and reliability of your coach bus for every journey. Prioritize these checks to avoid downtime and guarantee a smooth ride for your passengers.

https://myprevost.net/wp-content/uploads/2024/09/728x90.jpg