Why Are My Prevost Coach Bus Electrical Issues Occurring?

When flickering lights, dead batteries, and blown fuses plague your Prevost Coach bus, you're not just dealing with simple annoyances; you're facing potential electrical system failures. These issues can arise from a variety of sources, including worn-out components, faulty wiring, or excessive electrical loads. Identifying the root cause is essential, but where do you start? Understanding the nuances of your bus's electrical system can help you address these problems effectively and guarantee reliable performance on the road.

Common Electrical Problems

Identifying common electrical problems in Prevost coach buses is essential for maintaining ideal performance and safety. You'll often encounter issues like flickering lights, malfunctioning appliances, or dead batteries, which can stem from inadequate battery maintenance or outdated systems. These problems not only disrupt your travel experience but can also pose safety risks on the road.

To combat these issues, start by regularly inspecting your battery connections and verifying they're clean and tight. Corroded terminals can lead to poor electrical flow, causing various onboard failures. Additionally, consider implementing electrical upgrades that enhance system efficiency and reliability. Upgrading components such as wiring, fuses, or even the battery itself can dramatically improve performance.

You should also be aware of the symptoms of electrical issues. If you're experiencing frequent blown fuses or intermittent power loss, these could indicate deeper problems in your electrical system. Addressing these common electrical problems proactively verifies you maintain the freedom to roam without the hassle of unexpected breakdowns. By prioritizing battery maintenance and considering necessary electrical upgrades, you can keep your Prevost coach bus running smoothly and safely for your adventures ahead.

Checking the Battery System

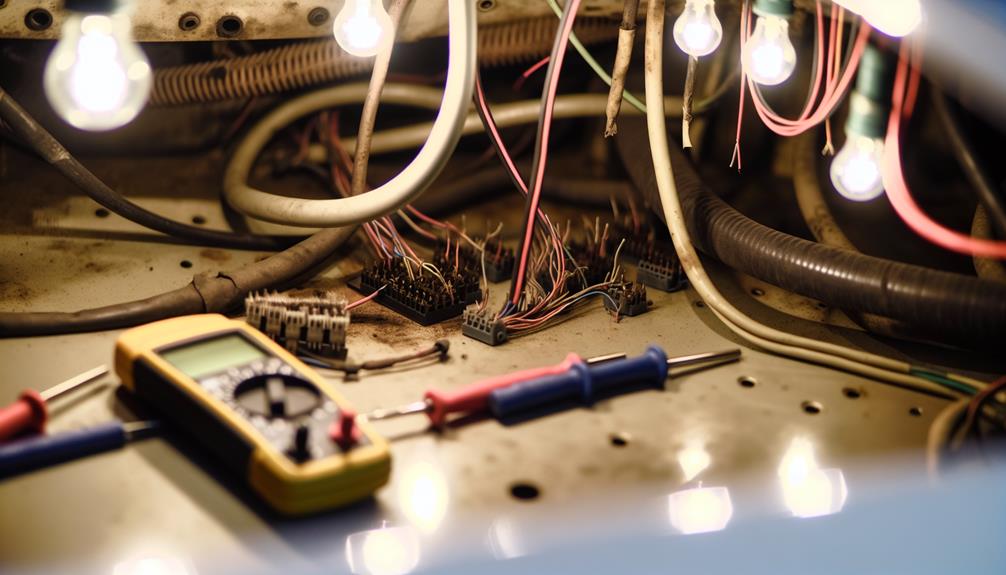

When checking the battery system in your Prevost coach bus, it's crucial to guarantee that every connection is secure and free from corrosion. Start by inspecting the terminals and cables for any signs of wear or buildup. Corroded terminals can impede voltage stability, leading to unreliable power supply and potential electrical issues.

Next, assess the battery's charge level with a multimeter. A healthy battery should show a voltage between 12.4 and 12.7 volts when fully charged. If your readings are lower, consider recharging or replacing the battery. Regular battery maintenance guarantees peak performance and longevity, allowing you to enjoy the freedom of the open road without interruptions.

Don't forget to check the battery's age as well. Most batteries last between three to five years, and an aging battery can lead to unexpected failures. Look into the battery's specifications and confirm you're using the right type for your coach.

Inspecting Wiring Connections

A thorough inspection of wiring connections is essential for maintaining the electrical integrity of your Prevost coach bus. Start by examining the wiring insulation for any signs of wear, fraying, or cracking. Damaged insulation can lead to short circuits or electrical failures, jeopardizing your freedom on the road.

Next, focus on the connectors. Look for any signs of connector corrosion, which can impede electrical flow and result in intermittent issues. Corrosion often appears as a green or white powdery substance around the metal connections. If you find any corroded connectors, clean them using a suitable contact cleaner and a soft brush. In some cases, you may need to replace the connectors entirely to guarantee a secure connection.

While inspecting, don't forget to check for loose connections. Even slightly loose connections can disrupt electrical continuity, causing problems that might leave you stranded. Tighten any loose connections securely, and consider using dielectric grease to protect against future corrosion. By systematically inspecting wiring connections, you'll help guarantee that your Prevost coach bus operates smoothly, allowing you to enjoy the open road with confidence.

Testing Fuses and Relays

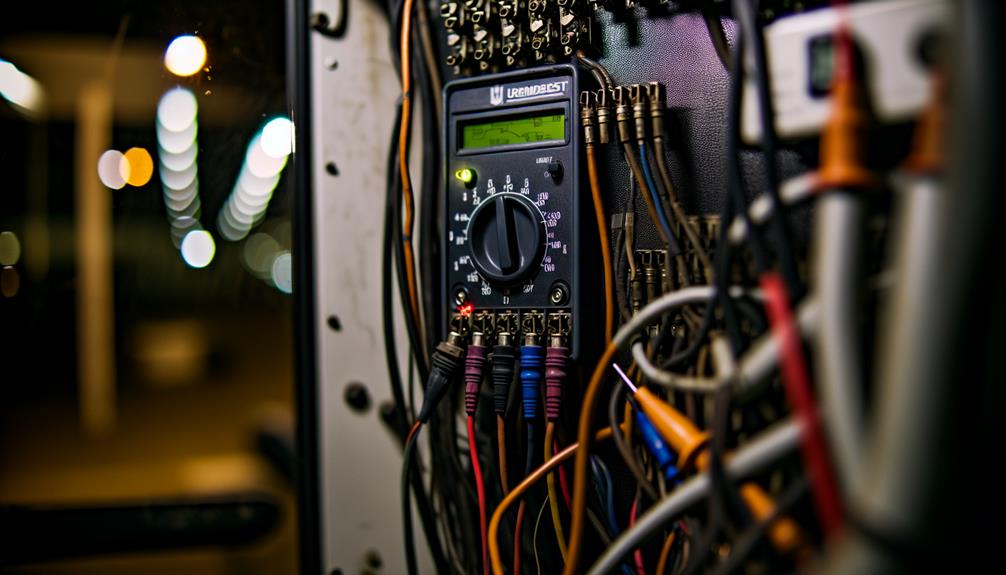

Regularly testing fuses and relays is essential for diagnosing electrical issues in your Prevost coach bus. Fuses protect your bus's electrical systems from overloads, while relays control the flow of electricity to various components. Start by identifying the fuse box and checking the relevant fuses using a multimeter. Look for continuity; a lack of it indicates the need for fuse replacement. Make sure to replace fuses with the correct amperage to avoid further complications.

Next, focus on relay testing. Relays can fail over time, leading to malfunctions in high-current circuits. To test a relay, remove it from its socket and use the multimeter to check for continuity across the terminals. If you find no continuity, the relay needs to be replaced. For added reliability, consider using a test light to verify that the relay is receiving power.

Analyzing Grounding Issues

Grounding issues can greatly disrupt the electrical systems in your Prevost coach bus, leading to a host of operational problems. If your bus experiences intermittent power loss or erratic electrical behavior, it's vital to analyze your grounding setup. Poor grounding can result from loose connections or degraded grounding equipment, causing voltage fluctuations and potential damage to sensitive components.

Start by inspecting all grounding connections. Verify that they're tight, clean, and free of corrosion. Utilize appropriate grounding techniques to enhance the integrity of your connections. For instance, consider using star washers to improve contact between surfaces and prevent loosening over time.

Next, confirm that your grounding points are correctly placed. They should be connected to a solid chassis ground to minimize resistance. If you suspect that your existing grounding setup isn't effective, upgrading to heavier gauge wire may provide better conductivity and reliability.

Don't overlook the importance of grounding in maintaining the overall functionality of your electrical systems. By addressing these grounding issues proactively, you can guarantee your Prevost coach bus operates smoothly, giving you the freedom to travel without electrical interruptions.

Evaluating the Charging System

Evaluating the charging system of your Prevost coach bus is essential for guaranteeing reliable operation and preventing unexpected power failures. Start by inspecting the alternator, as it's the core component responsible for charging your batteries while the engine runs. Look for signs of wear, such as unusual noises or overheating, which could indicate a need for charging system maintenance.

Next, conduct a battery performance evaluation. Check the battery terminals for corrosion and verify they're tightly connected. A weak or malfunctioning battery can lead to inadequate power supply, affecting your bus's overall performance. Test the voltage output from the alternator; it should typically be between 13.5 to 14.5 volts when the engine's running. If it's outside this range, it could signal an issue.

Additionally, examine the wiring and connections in the charging system. Frayed wires or loose connections can create resistance, hindering the charging process. Regularly maintaining your charging system not only enhances battery life but also supports your desire for freedom on the road, allowing you to focus on your travels without electrical worries. Keep these checks routine to guarantee a seamless journey.

Monitoring Electrical Load

After confirming your charging system operates effectively, the next step is to monitor the electrical load on your Prevost coach bus. Keeping a close eye on your power distribution is essential for maintaining peak performance and preventing potential issues. Load balancing guarantees that your electrical system functions efficiently, reducing the risk of overloads or failures.

To effectively monitor your electrical load, consider these key practices:

- Use a multimeter to measure voltage and current, verifying your readings are within acceptable ranges.

- Track the usage of high-demand appliances to identify any irregular spikes that may indicate a problem.

- Implement load management strategies to distribute electricity evenly across your system.

Diagnosing Lights and Signals

When troubleshooting lights and signals on your Prevost coach bus, it's vital to dig deep into the electrical system to pinpoint any issues. Start by checking the bulb types installed in your vehicle. Verify you're using the correct wattage and specifications; mismatched bulbs can lead to erratic behavior. If a bulb is burned out, replace it and observe the signal patterns.

Next, inspect the wiring and connections leading to the lighting system. Look for loose connections, frayed wires, or corrosion that could disrupt the current flow. A multimeter can help you measure voltage and continuity, revealing any hidden faults.

Pay attention to the signal patterns emitted by your turn signals and brake lights. If they blink rapidly or don't illuminate consistently, it may indicate a faulty relay or a short circuit somewhere in the system.

Lastly, consider the ground connections; they often get overlooked but are vital for proper functionality. A solid ground can eliminate many electrical quirks. By systematically checking these components, you'll narrow down the root cause of your lighting issues and restore functionality to your Prevost coach bus.

Understanding Control Panels

Understanding the control panels in your Prevost coach bus is key to managing its electrical systems effectively. These panels are the nerve center for various control panel functions, allowing you to monitor and adjust your bus's electrical systems with precision. Familiarizing yourself with them enables you to identify issues before they escalate.

Here are a few critical aspects of control panels to take into account:

- Indicators: Monitor battery levels, voltage, and electrical load to guarantee peak performance.

- Switches: Control lighting, HVAC, and other systems directly from the panel, making it easier to troubleshoot problems.

- Diagnostic Tools: Utilize built-in diagnostics to run troubleshooting techniques, pinpointing potential issues quickly.

When you encounter electrical problems, refer to the control panel first. Check for warning lights and error codes that can guide your troubleshooting efforts. Understanding these elements empowers you to take charge of your bus's electrical health, assuring reliability and freedom on the road. By mastering the control panels, you'll enhance your problem-solving skills and keep your Prevost coach bus running smoothly.

Seeking Professional Help

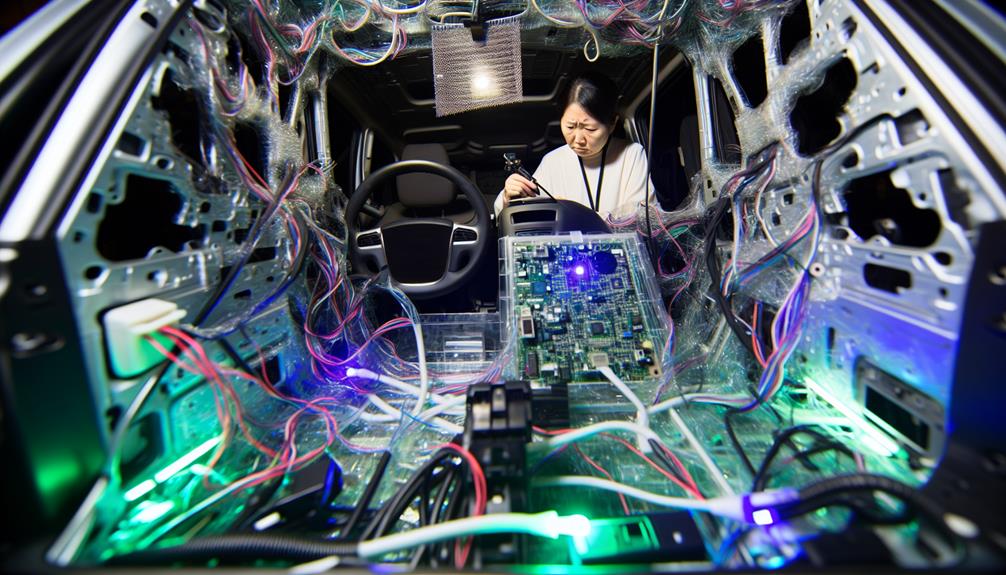

Seeking professional help can often be the most effective way to resolve complex electrical issues in your Prevost coach bus. When you encounter persistent electrical problems, it's crucial to recognize that DIY solutions may not suffice. Professional diagnostics provide an all-encompassing approach to identifying underlying issues that you might overlook. Trained technicians leverage specialized tools and knowledge to pinpoint faults in the electrical system, ensuring accurate assessments.

Electrical troubleshooting requires a systematic approach to isolate and rectify problems. These experts can interpret error codes, analyze wiring diagrams, and conduct thorough inspections that you may not have the resources to perform. With their experience, they can also anticipate potential future issues, giving you peace of mind as you travel.

While it may be tempting to tackle these challenges independently, the complexity of modern electrical systems demands a level of expertise that only professionals possess. By enlisting their help, you not only save time but also prevent further damage to your bus's electrical infrastructure. Embracing professional assistance empowers you to enjoy the freedom of the open road without the anxiety of unresolved electrical issues.

https://myprevost.net/wp-content/uploads/2024/09/728x90.jpg